main reasons for kiln shelf cracking

Dear new and old customers,

Hello everyone! If the kiln shelf cracks occasionally, it may be due to quality issues. If it happens frequently, it can basically be confirmed to be caused by improper use. Below is a collation of the main reasons for kiln shelf cracking – please pay close attention:

Moisture in the kiln shelf or works

The kiln shelf is stored in a humid environment, or the works are loaded into the furnace without being fully dried. In short, loading into the furnace without complete drying can cause cracking. After use, the kiln shelf should be placed in a dry and ventilated environment. If cleaned or self-sprayed with alumina, it must be dried before use. Products must be dried before loading into the furnace, especially for customers in southern regions where air humidity is high. Never load into the furnace after just a short air-dry! Dipping glaze and directly loading into the furnace is extremely harmful to the kiln shelf – it can be fatal!

Extreme temperature changes

Common scenarios involve furnace door opening time and firing time. The furnace door should be opened after naturally cooling to around 100°C. During cooling, do not blow air or open the furnace door wide immediately. When removing the kiln shelf, do not place it directly on a cold floor; wait until it cools to room temperature or remove it after cooling. During firing, try to raise and lower the temperature slowly – avoid sudden temperature changes. Uneven heating can also cause the kiln shelf to crack, such as when the flame is positioned to spray directly at a corner or part of the kiln shelf, or when resistance wires only heat certain areas, leading to uneven heating of the kiln shelf.

Hidden cracks inside the kiln shelf

During handling of the green body after slip casting, internal hidden cracks may form due to force. This situation has a low occurrence rate because the factory inspection process includes a step of tapping with a rubber hammer – kiln shelves with hidden cracks will break immediately. However, there is still a possibility of kiln shelves with hidden cracks slipping through. Generally, kiln shelves with hidden cracks will crack after the first firing, making them easy to identify. If the kiln shelf undergoes one or several firing cycles without cracking, the hidden crack scenario can basically be ruled out.

External force damage or improper operation

This mainly includes transportation damage and handling collisions. Based on our company’s years of transportation and packaging experience, current packaging can basically prevent transportation damage, unless logistics personnel deliberately collide with it. During loading/unloading and unpacking, try to avoid collisions, and also avoid collisions with hard objects during furnace loading or storage. When placing the kiln shelf, ensure it is stable – stand it vertically on a shelf or place it horizontally on a flat surface. Inspect the kiln shelf for cracks before use.

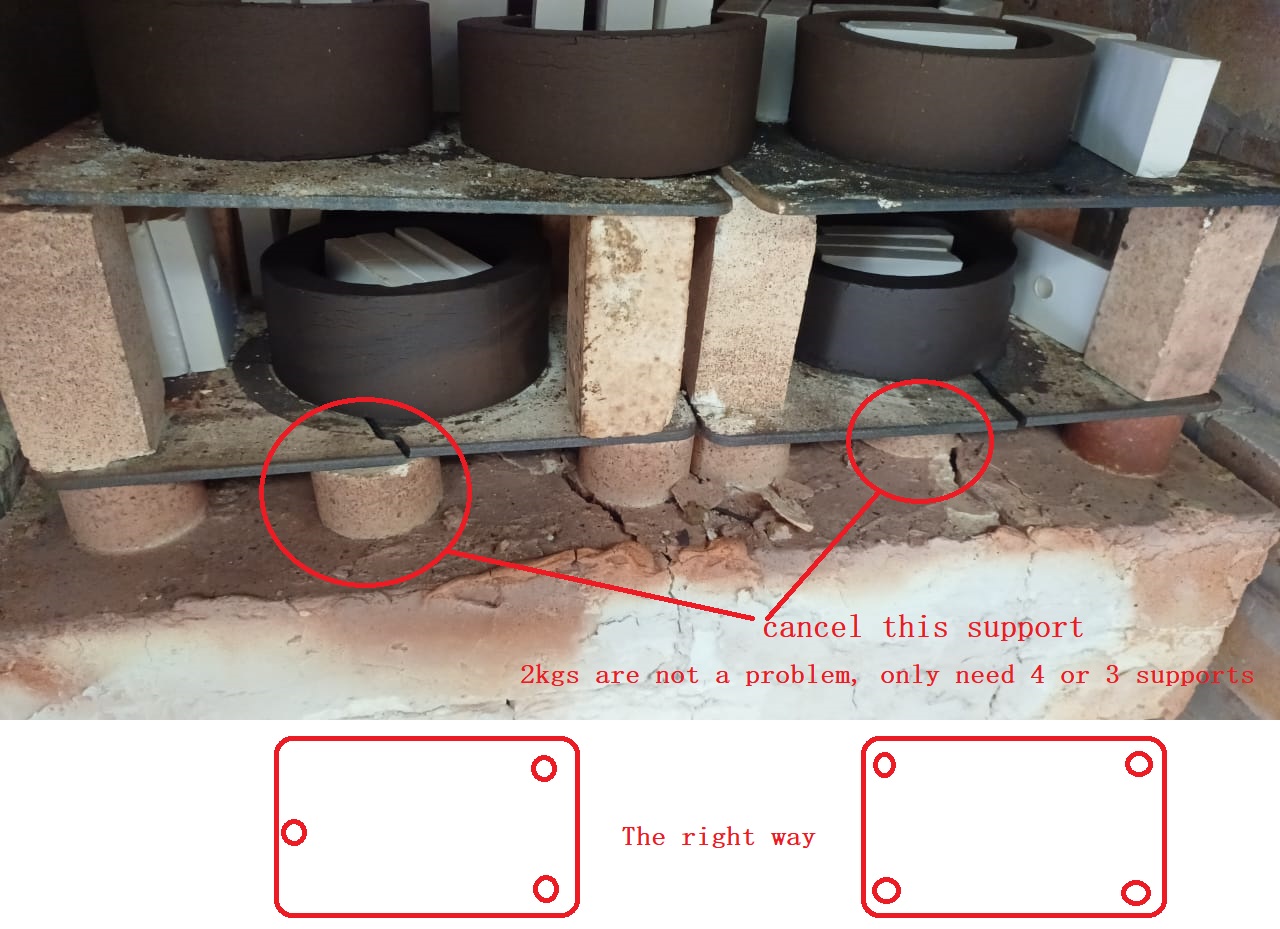

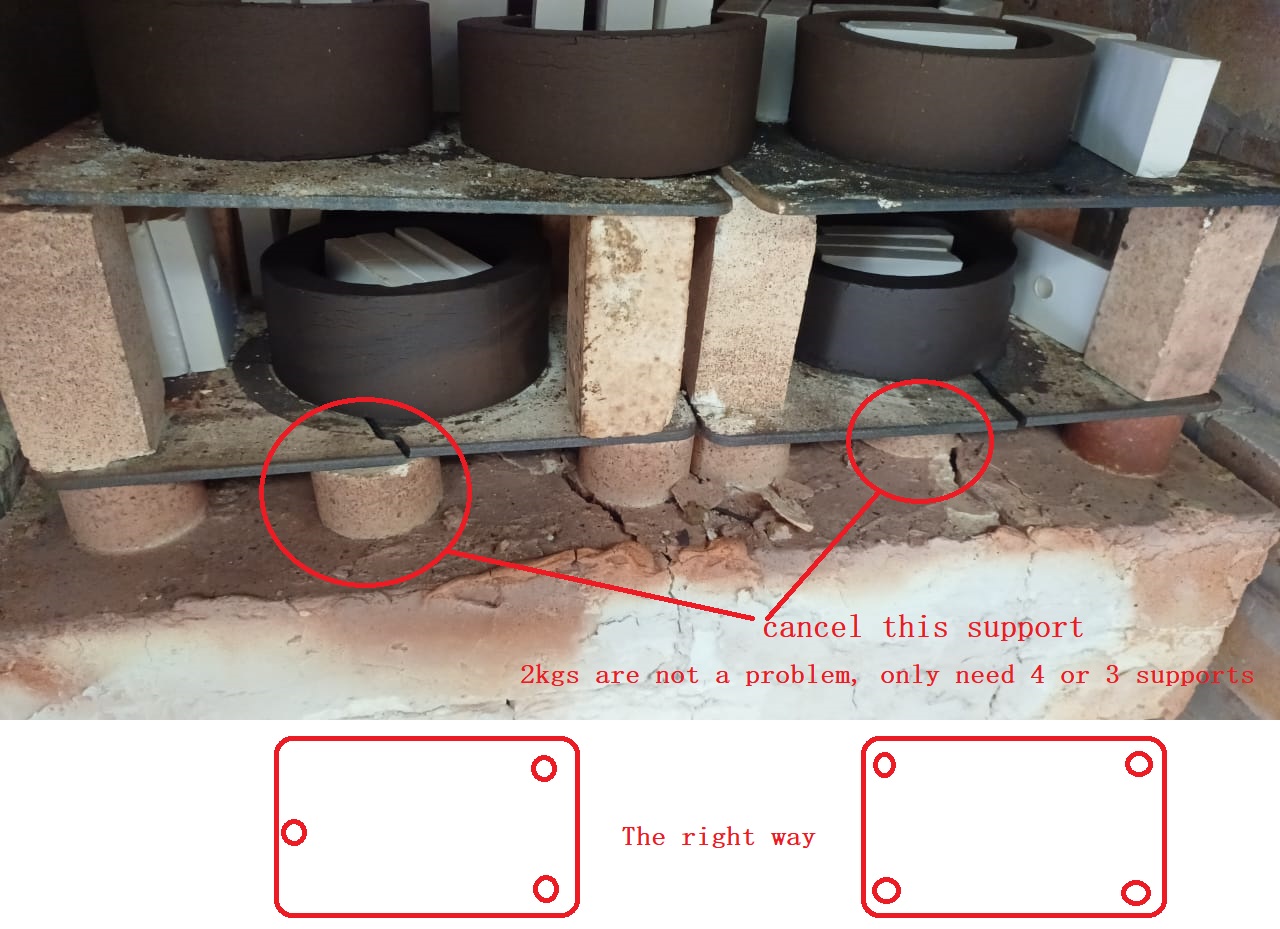

Uneven stress distribution

This refers to the stress points of the kiln shelf after loading into the furnace. The normal usage method is 3-point support, while square kiln shelves can use 4-point or 4-corner support. Never place stress points under the middle of the kiln shelf or arbitrarily add stress points on the sides or edges. The reason is that the expansion coefficient of the columns is relatively large, and their height tolerance is also significant. When the loaded works are heavy, arbitrarily added columns may expand unevenly with the corner columns during firing due to height tolerance, causing the kiln shelf to be cracked by the upward pressure.

【 Go Back 】 | 【 Print 】